We are all concerned about the amount of plastic that we use, but it is very hard to avoid. Plastic bottles are everywhere. Crystal Geyser is such a great partner with us at Lassen’s, so it’s nice to know that they are doing their part to recycle. They felt the same concern, and knew they had to be part of the solution.

A couple of us at Lassen’s went out to San Bernardino to tour the Crystal Geyser recycling plant. This plant has the capacity to process 35 million pounds of rPET (recycled PET plastic) per year. They told us that this is the equivalent of nearly 1 billion plastic bottles!

New Bottles From Old

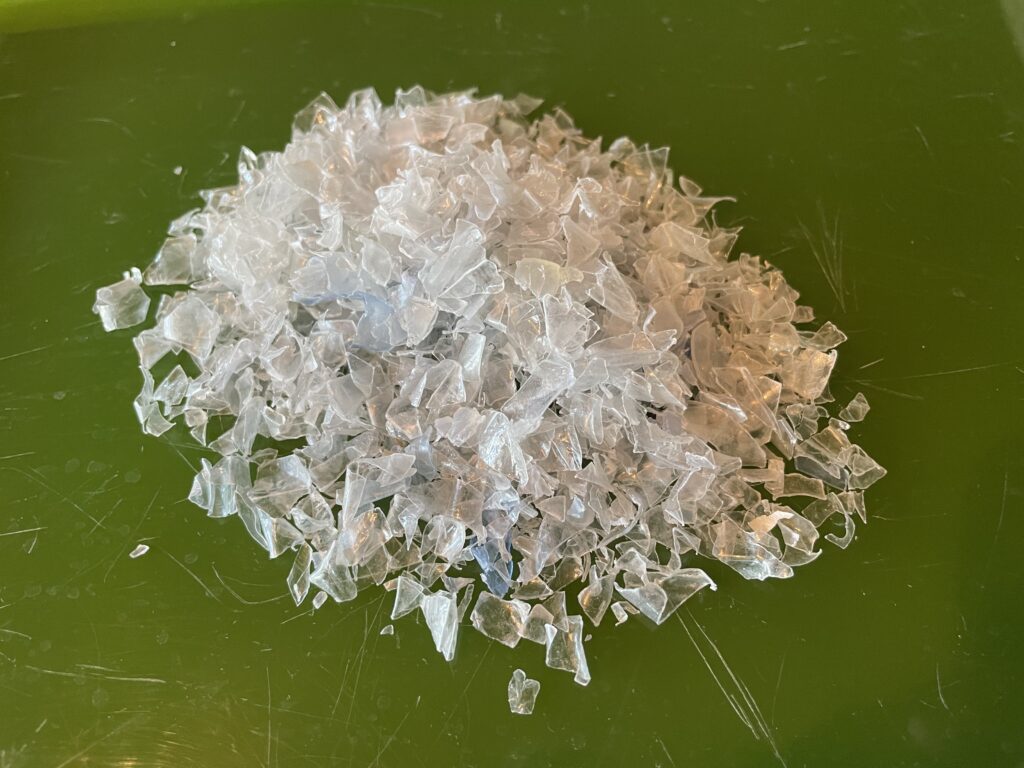

It was so interesting to see how they are making their bottles from old. The company receives sorted, cleaned, and shredded plastic from the California Recycling System.

These flakes look like they might be ready for processing, but far from it! There are particles of metal and other foreign items that need to be removed. The plastic is purified by heating to 545 degrees and then filtered five time to remove contaminants.

The design of the plant makes transitions from one station to another smooth and simple. The shredded plastic is fed into the machinery that heats, filters, and then processes it into the next useable form.

Let’s Clean it Up!

You can see how much has been removed from the shredded plastic on two of the filters shown. The filters on the upper right are unused. The lower filter is the first step, and it caught a lot of contaminants! The filter on the left catches smaller bits that went through the first. The waste left over after all those filters is actually sold to other recyclers to produce tech grade recycled materials.

After going through five filters, the remaining plastic is ready to mix 50/50 with new (virgin) PET (polyethylene terephthalate). According to the Crystal Geyser scientists, “PET requires less energy to manufacture than nearly all other bottles and is 100% recyclable.”

While it would be ideal to have the bottles made from 100% recycled plastic, right now it isn’t feasible. Every time plastic is recycled, it loses strength and flexibility, which are important qualities in water bottles. After mixing the rPET and Virgin PET, it is made into strings like spaghetti and then cut into rice-grain sized pellets.

The pellets then go through a “pellet flush,” where hot air (315 degrees) is shot through the pellets. This removes any toxic chemicals left after the other processes.

Testing, Testing!

At each step along the way, the Crystal Geyser chemists are busy testing. They make sure that the finished product exceeds FDA requirements for food grade plastic. We toured their lab and saw the tests that they were running on each batch. If any batches do not meet their standards, the process starts all over again with heating and filtering.

I asked the chemists if they could foresee a time when plastic bottles would be made from 100% recycled materials. They were optimistic! It would require us all to be more vigilant about recycling every plastic bottle we use. Used plastic ends up in landfills — or worse, into our waterways — so make sure to recycle! If there were more recycling, there would be more materials to work with and greater incentive to improve the process. So let’s all pitch in to help!

Crystal Geyser ships the rPET pellets to Crystal Geyser’s two bottling plants in Olancha and Shasta. There, the pellets are turned into bottle “preforms.” These preforms are heat expanded into 16oz bottles, and filled with that delicious spring water! On the left you can see the top screw-threads of a bottle. They also make their own preforms and bottles for the other sizes.

Touring the Crystal Geyser plant has made me feel better about the times when I have to buy bottled water. It has also made me more aware of how important recycling really is!

Independent and Family Owned, Just Like Lassen’s!

Crystal Geyser is a family-owned company that’s been bottling water at the source for over 30 years. Learn more about them by visiting https://www.crystalgeyserplease.com/

We love supporting other independent, family-owned businesses!